Freezer Ice Maker Troubleshooter

Select the symptoms you're experiencing below to get targeted troubleshooting steps:

Key Takeaways

- Check water supply and inlet valve before opening the freezer.

- Verify the freezer temperature is set between -18°C and -15°C.

- Inspect the ice mold, thermostat, and fan for blockages or failures.

- Perform a quick reset of the ice maker module to clear electronic glitches.

- If you spot a cracked water filter or a faulty defrost timer, call a professional.

When your freezer suddenly stops making ice, it feels like a small disaster - especially if you rely on ice for drinks, smoothies, or medical needs. The good news? Most of the time the issue is fixable with a few tools and a bit of patience. Below we walk through the most common culprits, how to diagnose each one, and step‑by‑step fixes you can try right at home.

Freezer ice maker is a built‑in appliance component that automatically produces ice cubes by filling a mold with water, freezing it, and then ejecting the cubes into a storage bin. It relies on a network of sensors, valves, and motors to work correctly.

1. Verify the Basics: Power, Settings, and Water Supply

Before you start pulling parts apart, make sure the obvious things are in order.

- Power check: Ensure the freezer is plugged in and the circuit breaker hasn’t tripped. Look for a blinking indicator light on the ice maker module - many models use this as a status signal.

- Temperature setting: The freezer should sit between -18°C and -15°C (0°F to 5°F). If the thermostat is set too warm, the ice mold never freezes solid. Adjust the dial and give the unit 4‑6hours to stabilize.

- Water line: Most ice makers draw water from a dedicated line behind the appliance. Inspect the hose for kinks, frozen sections, or pinch points. Detach the hose (turn off the water valve) and briefly blow through it to confirm flow.

If any of these checks reveal an issue, fixing it often restores ice production instantly.

2. The Water Inlet Valve - The Heartbeat of Ice Production

The water inlet valve opens for a few seconds each cycle, letting water rush into the ice mold. A faulty valve is the #1 reason ice makers stop working.

- Symptoms: No water fills the mold, a dripping hose, or a humming sound without water.

- Diagnosis: Listen for a click when the ice maker initiates. If you hear the click but no water, the valve may be clogged or the solenoid coil has burned out.

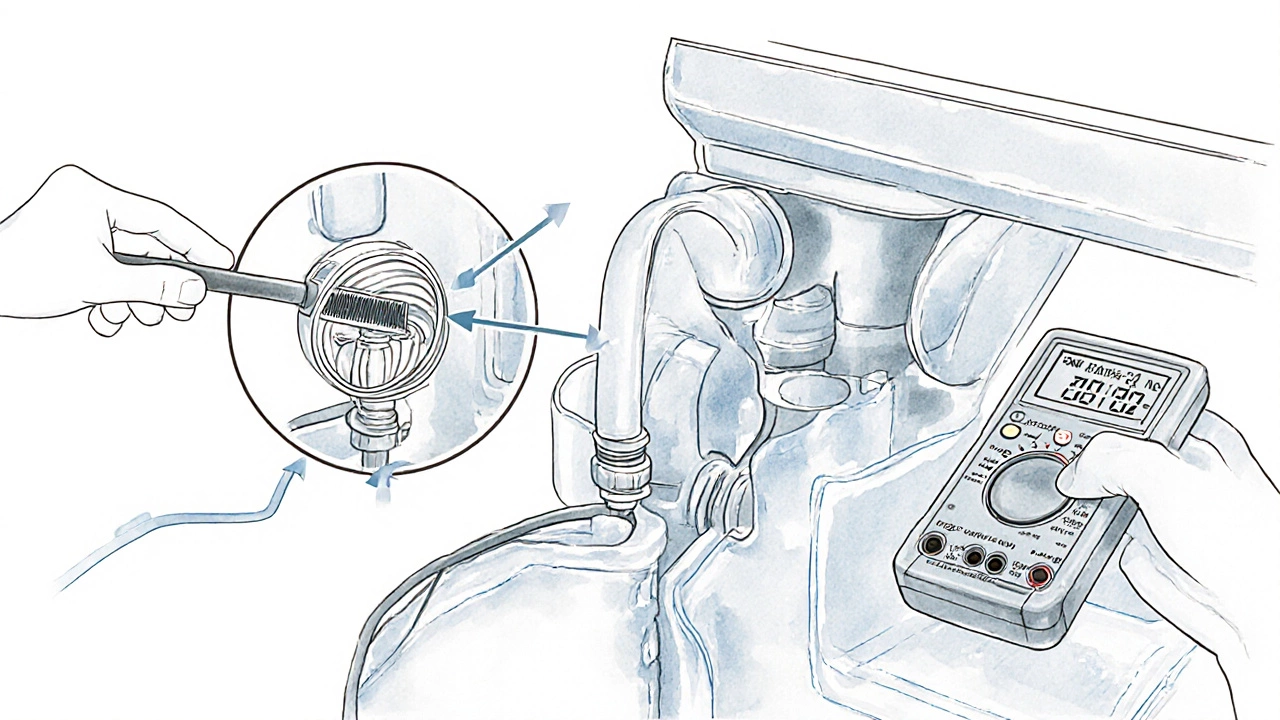

- Fix:

- Turn off the freezer and the water supply.

- Locate the valve (usually at the back, attached to the water line).

- Remove the attached hose and use a small brush to clear mineral buildup.

- Test the valve with a multimeter - it should show 20‑30Ω resistance. Replace the valve if the reading is open or infinite.

- Reinstall, turn the water back on, and run a test cycle.

Replacing a valve typically costs $30‑$60 for the part plus a few minutes of labor.

3. Ice Mold and Ejector Issues - Why Cubes Don’t Drop

Even if water fills the mold, the cubes won’t appear if the mold is cracked or the ejector arm can’t move.

- Cracked mold: Visible cracks let water leak out, preventing proper freezing. Swap the mold with a spare if your model offers one.

- Stuck ejector arm: Ice can jam the arm, especially if the freezer temperature is too low. Gently free the arm using a plastic spatula; avoid metal tools that could damage the mechanism.

- Ice buildup: Frost may accumulate around the mold, freezing the arm. Run a quick “defrost” by unplugging the freezer for 30minutes, then wipe away excess ice.

After clearing any blockage, run a couple of cycles to confirm that cubes are now dropping into the bin.

4. The Thermostat and Temperature Sensors - Keeping the Freeze Right

Modern freezers use electronic sensors (thermistors) to tell the compressor when to chill. If a sensor reads too high, the freezer won’t reach the ice‑making temperature.

- Symptoms: Ice cubes are soft, warped, or never form.

- Diagnosis: Use an infrared thermometer to measure the interior air. It should read around -16°C when the freezer is running. If it’s significantly higher, the sensor or the control board may be at fault.

- Fix: Test the sensor resistance at room temperature (typically 10kΩ). Replace if out of spec; otherwise, the main control board may need replacement.

Sensor replacement is usually under $20, while a control board can range $120‑$250 - a point where many homeowners call a professional.

5. The Freezer Fan and Evaporator Coil - Airflow Matters

Even with a working valve and mold, poor airflow can keep the freezer from freezing water fast enough.

- Fan failure: A silent fan suggests a burnt motor or a blocked fan blade. Remove the back panel, locate the fan, and spin it by hand. If it resists, replace the motor.

- Frosted evaporator coil: Ice buildup on the coil reduces heat exchange. Defrost the freezer (manual or auto‑defrost cycle) and clean the coil with a soft brush.

Both fan and coil maintenance are inexpensive DIY tasks, often under $15 for cleaning supplies.

6. Resetting the Ice Maker Module - When Electronics Glitch

Occasionally the ice maker’s control module gets confused, especially after a power outage.

- Unplug the freezer for 2‑3minutes.

- Plug it back in and locate the reset button (sometimes hidden behind the ice bin). Press and hold for 5‑10seconds.

- The indicator light should flash, indicating a reboot. Allow the unit to complete a full cycle (about 90minutes).

If the reset doesn’t bring back ice, move on to the component checks above.

7. When to Call a Professional

Some problems require tools or expertise beyond a typical DIY toolbox.

- Repeated valve failures after replacement.

- Control board diagnostics or firmware updates.

- Leak detection involving sealed refrigeration lines.

- Complex defrost timer or sensor network issues.

Professional repairs in Auckland usually cost $80‑$150 for labor, plus parts. Always ask for a clear quote before authorizing work.

8. Preventive Maintenance - Keep Ice Coming Year‑Round

Regular upkeep can stop most ice‑maker breakdowns before they start.

- Change the water filter: If your freezer has a built‑in filter, replace it every 6‑12months. A clogged filter reduces water pressure, leading to incomplete mold fills.

- Clean the ice bin: Spills can attract mold. Wipe the bin with a mild soap solution weekly.

- Check door seals: A leaky gasket lets warm air in, raising interior temperature. Run a dollar‑bill test; if the bill slides out easily, replace the seal.

- Run a monthly defrost: Even with auto‑defrost, a quick manual melt helps keep the evaporator coil clear.

Following these tips adds only a few minutes each month but saves hours of troubleshooting later.

| Issue | Typical Symptom | Quick Fix | When to Call Pro |

|---|---|---|---|

| Closed water inlet valve | No water in mold | Clear valve, test resistance | Valve repeats failure after replacement |

| Ice mold cracked | Leaking water, soft cubes | Replace mold | Unable to source OEM part |

| Frozen water line | Hissing sound, no water | Warm the line with a hair dryer | Line repeatedly refreezes |

| Thermostat too warm | Warm, slushy cubes | Adjust temperature setting, clean condenser | Temperature won’t stay set |

| Fan motor failure | Freezer not cold enough | Inspect and replace fan motor | Motor replacement needed |

Frequently Asked Questions

Why does my ice maker stop after a few days?

Most often the water inlet valve clogs with mineral deposits, or the ice mold freezes solid due to a too‑low temperature setting. Clean the valve and verify the thermostat is set between -18°C and -15°C.

What does a constant clicking sound mean?

A click usually means the ice‑maker’s control board is trying to start a cycle, but the water valve isn’t opening. Check the valve’s voltage with a multimeter; replace if there’s no voltage.

Can a frozen water line be fixed without a professional?

Yes. Turn off the water supply, unplug the freezer, and gently warm the line with a hair dryer for a few minutes. Once thawed, run a test cycle to ensure water flows freely.

How often should the water filter be changed?

If your model includes a filter, replace it every 6‑12months or after 200gallons of water, whichever comes first. A clogged filter reduces pressure and can stop ice production.

Is it safe to use a DIY reset button on the ice maker?

Yes, as long as you follow the manufacturer’s reset procedure - unplug, wait a few minutes, then press the reset button. This clears minor electronic glitches without harming the unit.